Installation Kits

|

Tip Extraction Installation Kits |

| KIT #: | APPLICATION: | ||

| XYKT-3 XYKT-8 XYKT-15 |

HC-3, Three Tip Kit HC-8, Eight Tip Kit HC-15, Fifteen Tip Kit |

KIT CONTENTS

| XYKT-3 | XYKT-8 | XYKT-15 | Drawing | |

| KT-T3225 32mm Ø tube 2.5m |

4 | 8 | 11 |  |

| KT-32T T-section / 32mmØ |

3 | 4 (one with sleeve) |

|

|

| KT-32TC/S/P Cobra Clip w/ Screw |

8 | 16 | 22 |  |

| KT-FT3215 32mmØ Flex tube, 1.5 meter |

1 |  |

||

| KT-FT3225 32mmØ Flex tube, 2.5 meter |

1 | 1 |  |

|

| KT-32EC End cap, 32mmØ |

1 | 4 | 6 |  |

| 169-225 Iron connector plug |

4 | 10 | 20 |  |

ASSEMBLY MADE SIMPLE:

|

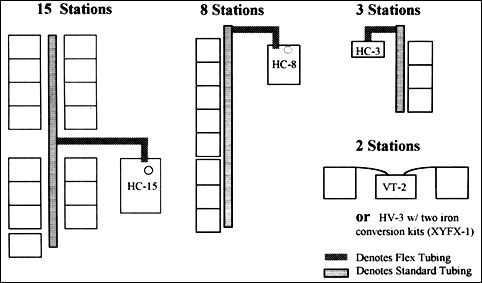

SUGGESTED LAYOUT:

Note: Actual setup will depend on the application and shop floor layout.